Full electric injection moulding for high performance on your production

Get started

What is ROBOSHOT?

FANUC ROBOSHOT takes state-of-the-art CNC precision technology from turning and milling and applies it to electric injection moulding. The results are greater acceleration, ultimate precision of movement and extremely short cycle times to produce large quantities of consistently high-quality parts.

Why choose ROBOSHOT?

With the release of the FANUC ROBOSHOT ALPHA-SiB series of injection moulding machines, customers receive all the benefits that fully electric machines are renowned for providing, such as stability, high precision and low maintenance costs. An installed global base of 65,000 users provides testimony to the ROBOSHOT brand. The latest ALPHA-SiB series offers numerous enhancements to the machine’s control, ensuring that advanced software and machine performance combine to provide customers with genuine competitive gain.

Which models of ROBOSHOT?

The ALPHA-SiB series is available in a number of models catering for capacities from 15 to 450 tonne to suit virtually all applications and sectors. Whether working in the automotive, aerospace, medical, consumer product, food, electronic, agriculture, construction, telecommunications or any other industry, the ALPHA-SiB series can help to optimise production. The machines are also available with a dedicated MIM (metal injection moulding) CIM (ceramic injection moulding), LSR (liquid silicone rubber) and thermoset injection package soon.

Send us a message!

Discover our ROBOSHOT MODELS

α-S30iB

- Clamp force (T)

- 30

- Tie bar spacing (mm)

- 310 x 290

- Min/Max. die height (mm)

- 330 - 150

- Clamp stroke (mm)

- 230

- Ejector stroke (mm)

- 60

- Injection speed mm/s

- 600

- Screw Range Ø (mm)

- Ø 18 – up to Ø 32

- Shot capacity (cm3)

- 9 – up to 29

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 3 x 1 x 1.5

Wide range of FANUC Roboshot standard features

α-S50iB

- Clamp force (T)

- 50 - 65

- Tie bar spacing (mm)

- 360 x 320

- Min/Max. die height (mm)

- 150 – 460

- Clamp stroke (mm)

- 250

- Ejector stroke (mm)

- 70

- Injection speed mm/s

- 350 - 550

- Screw Range Ø (mm)

- Ø 18 – up to Ø 32

- Shot capacity (cm3)

- 19 – up to 76

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 3.7 x 1.1 x 1.5

Wide range of FANUC Roboshot standard features

α-S100iB

- Clamp force (T)

- 100 - 125

- Tie bar spacing (mm)

- 460 x 410

- Min/Max. die height (mm)

- 150 – 620

- Clamp stroke (mm)

- 350

- Ejector stroke (mm)

- 100

- Injection speed mm/s

- 200 - 350 - 550

- Screw Range Ø (mm)

- Ø 22 – up to Ø 40

- Shot capacity (cm3)

- 29– up to 181

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 4.4 x 1.2 x 1.6

Wide range of FANUC Roboshot standard features

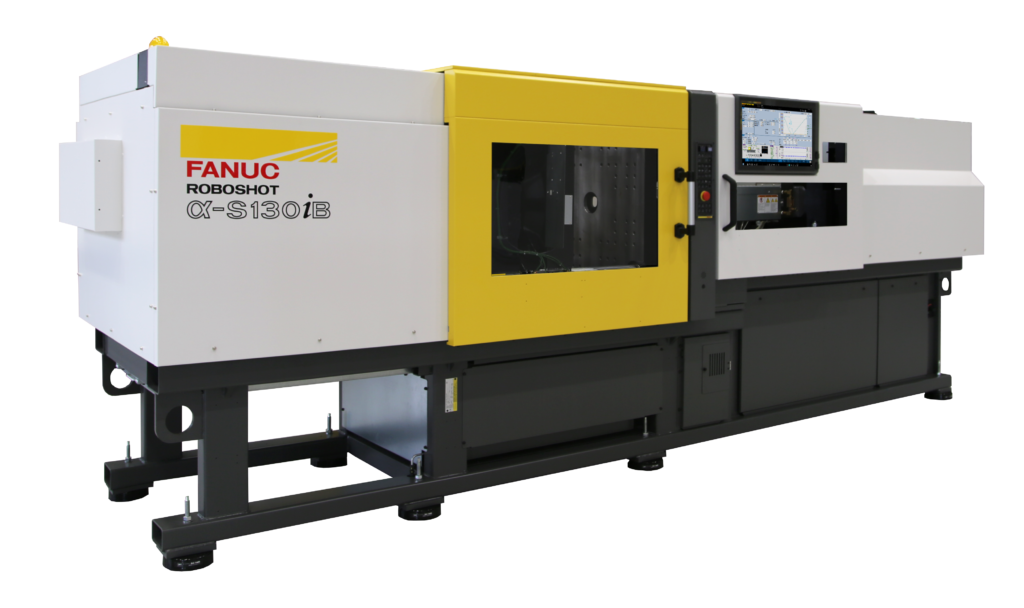

α-S130iB

- Clamp force (T)

- 130

- Tie bar spacing (mm)

- 530 x 530

- Min/Max. die height (mm)

- 200 – 670

- Clamp stroke (mm)

- 400

- Ejector stroke (mm)

- 100

- Injection speed mm/s

- 200 - 350 - 550

- Screw Range Ø (mm)

- Ø 26 – up to Ø 40

- Shot capacity (cm3)

- 50 – up to 181

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 4.6 x 1.4 x 1.6

Wide range of FANUC Roboshot standard features

α-S150iBs

- Clamp force (T)

- 150 – 180

- Tie bar spacing (mm)

- 560 x 510

- Min/Max. die height (mm)

- 200 – 675

- Clamp stroke (mm)

- 440

- Ejector stroke (mm)

- 150

- Injection speed mm/s

- 350 - 550

- Screw Range Ø (mm)

- Ø 22 – up to Ø 40

- Shot capacity (cm3)

- 29 – up to 181

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 4.9 x 1.4 x 1.7

Wide range of FANUC Roboshot standard features

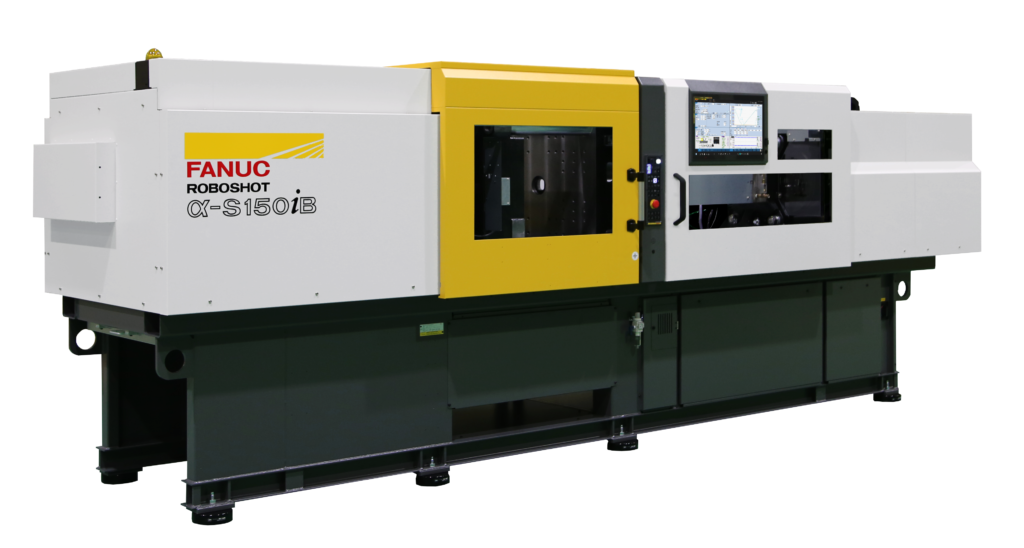

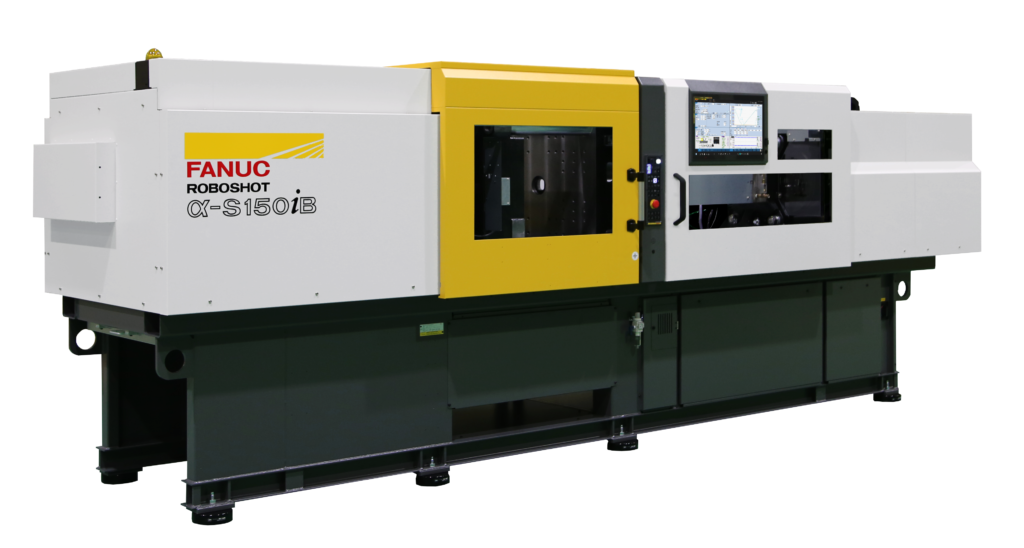

α-S150iB

- Clamp force (T)

- 150 – 180

- Tie bar spacing (mm)

- 560 x 510

- Min/Max. die height (mm)

- 200 – 675

- Clamp stroke (mm)

- 440

- Ejector stroke (mm)

- 150

- Injection speed mm/s

- 200 - 270 - 350

- Screw Range Ø (mm)

- Ø 32 – up to Ø 52

- Shot capacity (cm3)

- 121 – up to 442

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 5.5 x 1.4 x 1.7

Wide range of FANUC Roboshot standard features

α-S220iB

- Clamp force (T)

- 220

- Tie bar spacing (mm)

- 650 x 650

- Min/Max. die height (mm)

- 250 – 750

- Clamp stroke (mm)

- 550

- Ejector stroke (mm)

- 150

- Injection speed mm/s

- 200 - 270 - 350

- Screw Range Ø (mm)

- Ø 32 – up to Ø 56

- Shot capacity (cm3)

- 121 – up to 512

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 5.9 x 1.6 x 1.9

Wide range of FANUC Roboshot standard features

α-S250iB

- Clamp force (T)

- 250 - 300

- Tie bar spacing (mm)

- 710 x 635

- Min/Max. die height (mm)

- 650 - 300

- Clamp stroke (mm)

- 600

- Ejector stroke (mm)

- 200

- Injection speed mm/s

- 280 - 350

- Screw Range Ø (mm)

- Ø 32 – up to Ø 56

- Shot capacity (cm3)

- 121 – up to 640

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 6.4 x 1.8 x 1.9

Wide range of FANUC Roboshot standard features

α-S300iB small capacity

- Clamp force (T)

- 300 - 350

- Tie bar spacing (mm)

- 810 x 710

- Min/Max. die height (mm)

- 650 - 300

- Clamp stroke (mm)

- 600

- Ejector stroke (mm)

- 200

- Injection speed mm/s

- 280 - 350

- Screw Range Ø (mm)

- Ø 32 – up to Ø 56

- Shot capacity (cm3)

- 121 – up to 640

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 6.4 x 1.9 x 1.9

Wide range of FANUC Roboshot standard features

α-S300iB

- Clamp force (T)

- 300 - 350

- Tie bar spacing (mm)

- 810 x 710

- Min/Max. die height (mm)

- 650 - 300

- Clamp stroke (mm)

- 600

- Ejector stroke (mm)

- 200

- Injection speed mm/s

- 240 - 270

- Screw Range Ø (mm)

- Ø 40 – up to Ø 72

- Shot capacity (cm3)

- 188 – up to 1059

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 7 x 1.9 x 1.9

Wide range of FANUC Roboshot standard features

α-S300iB large capacity

- Clamp force (T)

- 300 - 350

- Tie bar spacing (mm)

- 810 x 710

- Min/Max. die height (mm)

- 650 - 300

- Clamp stroke (mm)

- 600

- Ejector stroke (mm)

- 200

- Injection speed mm/s

- 160

- Screw Range Ø (mm)

- Ø 64 – up to Ø 80

- Shot capacity (cm3)

- 901 – up to 1608

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 7.6 x 1.9 x 1.9

Wide range of FANUC Roboshot standard features

α-S450iB ultra small capacity

- Clamp force (T)

- 450 - 500

- Tie bar spacing (mm)

- 920 x 920

- Min/Max. die height (mm)

- 1000 - 350

- Clamp stroke (mm)

- 900

- Ejector stroke (mm)

- 250

- Injection speed mm/s

- 280 - 350

- Screw Range Ø (mm)

- Ø 40 – up to Ø 56

- Shot capacity (cm3)

- 188 – up to 640

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 8.3 x 2.2 x 2.2

Wide range of FANUC Roboshot standard features

α-S450iB small capacity

- Clamp force (T)

- 450 - 500

- Tie bar spacing (mm)

- 920 x 920

- Min/Max. die height (mm)

- 1000 - 350

- Clamp stroke (mm)

- 900

- Ejector stroke (mm)

- 250

- Injection speed mm/s

- 240 - 270

- Screw Range Ø (mm)

- Ø 48 – up to Ø 72

- Shot capacity (cm3)

- 318 – up to 1059

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 8.3 x 2.2 x 2.2

Wide range of FANUC Roboshot standard features

α-S450iB

- Clamp force (T)

- 450 - 500

- Tie bar spacing (mm)

- 920 x 920

- Min/Max. die height (mm)

- 1000 - 350

- Clamp stroke (mm)

- 900

- Ejector stroke (mm)

- 250

- Injection speed mm/s

- 160

- Screw Range Ø (mm)

- Ø 64 – up to Ø 80

- Shot capacity (cm3)

- 901 – up to 1608

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 8.9 x 2.2 x 2.2

Wide range of FANUC Roboshot standard features

α-S450iB large capacity

- Clamp force (T)

- 450 - 500

- Tie bar spacing (mm)

- 920 x 920

- Min/Max. die height (mm)

- 1000 - 350

- Clamp stroke (mm)

- 900

- Ejector stroke (mm)

- 250

- Injection speed mm/s

- 180

- Screw Range Ø (mm)

- Ø 68 – up to Ø 100

- Shot capacity (cm3)

- 1090 – up to 2827

- Screw Geometries

- Various to suit your process requirements

- Machine Dimensions (L x W x H) (m)

- 9.5 x 2.2 x 2.3

Wide range of FANUC Roboshot standard features

Enhanced control and software functionality

Large, high-resolution display

The unique AWF3 technology provides fast, reliable automatic threading in just 10 seconds under non-submerge condition . It allows automatic wire feeding up to 500 mm under submerge conditions depending on the machine configuration.

Easy maintenance

FANUC iH Pro can highlight impending issues prior to failure, even providing a video or image that outlines how rectification can take place in-house to minimise downtime. Furthermore, the inclusion of a hardened workpiece table as standard, prevents any potential for scratches to develop.

Faster injection rates

In support of the faster response times provided by the PANEL iH Pro HMI, notable machine performance enhancements include increased injection rates of up to 350 mm/s, helping customers to boost productivity. Among further performance-related improvements are higher standard injection pressures, expanded screw diameter availability and the potential for up to four-axis servo-core control.

Lifetime machine support

Thanks to a comprehensive Europe-wide network of service centres, FANUC can offer lifetime support for its machines, providing complete peace-of-mind for customers in the rare event of an issue.

Great Reliability

More than 35 years of experience and passion for highest precision results in high reliability. FANUC is very proud to produce high quality products that will work perfectly for a long time, supporting the customers to work effectively and to increase their productivity.

Sustainable Approach

We started our green journey more than 35 years ago with our first ROBOSHOT fully electric injection moulding machine.

Lowest energy consumption

FANUC’s superior servo technology and intelligent energy recovery system reduce ROBOSHOT’s electricity consumption by 50-70% compared with hydraulic machines, and by 10-15% in comparison with competitor electric machines. With its exceptionally low maintenance costs, very high levels of uptime, fewer components and less wear, FANUC ROBOSHOT provides the lowest total cost of ownership (TCO) on the market.

Increase your automation flexibility

Users can enjoy easy connection between ROBOSHOT and FANUC robot using the versatile FL-Net field bus system.

Enhance your mould shop planning with the IoT

FANUC LINKi2 is a product and quality information management tool that oversees up to 1000 ROBOSHOT machines in real time. You can access LINKi2 remotely via the web browser on your PC or tablet, or run it on the split-screen display of the new SiB series. LINKi2 can operate as a stand-alone tool or interfaced via Euromap 63 or 77 to permit data exchange with ERP or MES systems, thus meeting all of your future IoT requirements (up to 120 months of logged data).

For which companies is a ROBOSHOT suitable?

The ideal choice for your industry no matter what size

Medical industry

Automotive industry

Electrical industry

Optical industry

Packaging industry

LSR

Customer voices

Impressions on using FANUC ROBOSHOT